Spring plungers might seem like small components, but their role in various industries is crucial. In this article, we’ll delve into the world of spring plungers, focusing on Kipp spring plungers and their unique mechanics that involve the quarter turn lock mechanism. Let’s explore how these unassuming devices play a significant role in ensuring precision and functionality across different applications.

Understanding Spring Plungers

Spring plungers, also known as ball plungers or spring-loaded devices, are commonly used in situations where controlled spring tension is required. They are used to locate, stop, align, or latch parts in various mechanisms. These components are widely used in industries like manufacturing, automotive, aerospace, and electronics, to name a few.

Importance of Quarter Turn Lock Mechanism

The quarter turn lock mechanism has gained immense importance in industries that require quick and secure fastening. It offers a 90-degree rotational locking action, allowing for easy and efficient assembly and disassembly. This mechanism is a game-changer in scenarios where time and precision are paramount.

Introduction to Kipp Spring Plungers

Amid various options, Kipp spring plungers stand out for their innovative approach to addressing fastening needs. Kipp, a renowned manufacturer, has introduced spring plungers with a unique twist – the quarter turn lock mechanism. These plungers combine the advantages of traditional spring plungers with the efficiency of the quarter turn lock, resulting in a versatile and reliable solution.

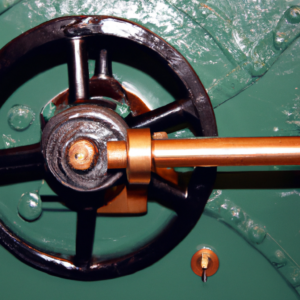

Mechanics Behind Kipp Spring Plungers

Kipp spring plungers consist of several key components that work harmoniously to achieve their function. The plunger body houses a spring-loaded ball, which interacts with the receiving bore to either lock or release the mechanism. When pressure is applied, the ball retracts, allowing the plunger to move freely. The quarter turn lock mechanism engages with a 90-degree rotation, providing a secure and stable lock.

Components of Kipp Spring Plungers

To understand the mechanics better, let’s break down the components of Kipp spring plungers:

- Plunger Body: The main housing that contains the spring and ball.

- Spring: Provides the necessary tension for the plunger’s movement.

- Ball: The spherical element that engages with the receiving bore.

- Receiving Bore: The counterpart that interacts with the ball, causing the locking action.

- Quarter Turn Lock Mechanism: The innovation that allows for quick and secure fastening.

Functioning of Quarter Turn Lock

The brilliance of Kipp spring plungers lies in their quarter turn lock mechanism. When the plunger is inserted into the receiving bore, a simple 90-degree rotation locks it into place. This mechanism eliminates the need for time-consuming threading or manual adjustments, making it ideal for applications where efficiency is paramount.

Advantages of Kipp Spring Plungers

Kipp spring plungers offer several advantages over traditional locking mechanisms:

- Rapid Fastening: The quarter turn lock allows for quick and effortless fastening.

- Precision: The locking action is highly accurate, ensuring consistent results.

- Versatility: Kipp plungers find applications in diverse industries due to their adaptability.

- Durability: Quality materials and construction contribute to their long lifespan.

Applications in Different Industries

The versatility of Kipp spring plungers makes them valuable in various industries:

- Manufacturing: Used for precise locating and positioning of components.

- Automotive: Ensures secure fastening of interior and exterior parts.

- Aerospace: Contributes to the reliability of critical components.

- Electronics: Provides quick-locking solutions in electronic assemblies.

Choosing the Right Kipp Spring Plunger

Selecting the appropriate plunger requires considering factors such as load capacity, size, and material. Consulting Kipp’s guidelines and experts can help ensure the right choice for the intended application.

Installation and Maintenance

Installing Kipp spring plungers involves inserting the plunger into the bore and rotating it. Regular maintenance includes cleaning, lubrication, and checking for wear to maintain optimal performance.

Comparing with Traditional Plungers

Compared to traditional threaded plungers, Kipp spring plungers offer a streamlined and efficient alternative. The quarter turn lock eliminates the need for threading, reducing assembly time and minimizing the risk of human error.

Innovations in Spring Plunger Technology

Recent advancements have led to improvements in materials, manufacturing processes, and lock mechanisms. These innovations continue to enhance the performance and reliability of spring plungers across industries.

Safety Considerations

While spring plungers are relatively simple devices, users must follow safety precautions when working with them. Wear appropriate protective gear and ensure proper installation to prevent accidents.

Conclusion

In the realm of precision fastening, Kipp spring plungers with the quarter turn lock mechanism have emerged as a game-changing solution. Their unique mechanics combine efficiency, accuracy, and versatility, making them indispensable across industries. As technology advances, these unassuming components continue to shape the way we approach assembly and disassembly tasks.